NEW PALESTINE — With 30 years of manufacturing experience under his belt, Dave Post decided several years ago that he wanted to get back into teaching — something he did for a couple years right out of college.

Post made his move from business back to education in time for the 2014-15 school year when he landed an engineering teaching position at New Palestine High School.

The move turned out to be one of the best decisions for Post, and it benefited students who like working with their hands. Post has helped the district create a one-of-a-kind manufacturing and construction department that gives students real hands-on work experience through all four years of high school.

Nearly a decade later, Post will retire after shaping the department and setting students up for success. Tim Tarplee, who Post brought on board a few years ago, will step into Post’s position.

“I am going to miss this job tremendously,” Post said. “I loved my job in manufacturing and I miss it, but not the way I’m going to miss being here at the high school. For the longest time I dreamed about getting back into teaching, and I’m glad I did.”

Principal Jim Voelz said it’s been a privilege to work with Post the past several years and that he’s made a world of difference to students.

“He has made a huge impact on our Industrial Tech Program, the school’s robotics team and the entire school culture,” Voelz said. “He will be missed by our students and his colleagues.”

From 2003 to 2013 Dan Ginther led the engineering classes at NPHS, which were geared toward production and transportation. He helped the students get the program Project Lead the Way going, which included Science Technology Engineering and Math (STEM) learning.

Ginther, however, had a vision to build the program up and offer more hands-on work experience to students, but he retired before he could make that happen. A couple years later, Post stepped in and has been able to bring that vision to reality. He’s created one of the largest and most-comprehensive manufacturing, construction and engineering programs in the state.

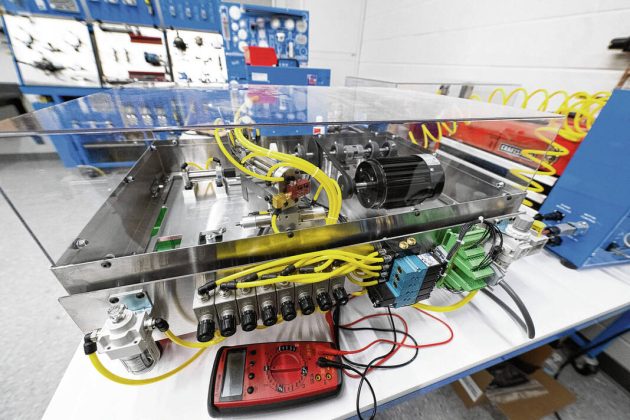

In addition to a massive work shop area, students have the latest training systems to learn from, including a new laser cutting machine, welders and various industry-level machinery.

“There were no year-long classes for kids when I first got here because construction was a semester and transportation was a semester and there was zero manufacturing,” Post said.

Post took over the classes the way they were but slowly started reading about grants given to districts willing to teach career tech educational classes.

“Once I got settled in, I really directed us toward manufacturing because that is my background,” Post said.

Indiana is second in the nation with 745 manufacturing jobs per 10,000 people, and it has the most concentrated manufacturing workforce in the nation. Post knew that fact equated to numerous job opportunities for students if they could get them interested and trained.

Post began meeting with administrators and turning in new class requests while dropping the transportation class and creating a year-long manufacturing class.

“Everything took off after that and we couldn’t fit everything in,” Post said.

That caused him to focus on offering a full year of manufacturing followed by a full year of construction, giving students two full years of real work experience. Now, students who enroll as freshman can take four full years of classes geared toward construction and manufacturing.

“I’d like to think we did that — change the face of the program,” Post said. “I’m a big believer in tech education.”

Post was so busy, teaching seven classes each day, that they had to add Tarplee, a second tech education teacher.

“I knew that was a big ask,” Post said. “For two years, I did the seven classes a day, but suddenly all this grant money started coming in and things changed. We got to hire that second teacher.”

Tarplee started teaching during the 2022-23 school year, which was perfect timing as state officials noted districts needed to provide students with different “pathways” toward graduation. That mindset fit Post’s thinking all along.

“We’re very lucky to have an educator like Tim,” Post said. “He’s a young guy who hopefully will stay here for a while, and he’s got his own ideas about how to make this program grow.”

Tarplee, who Post says has a tech education degree, handles the construction end of the program while Post has taught manufacturing. The district’s school board recently approved the hiring of James Hanson as the second industrial technology teacher to work with Tarplee and fill in Post’s spot when the school year is over.

“We have a quality program, so teachers want to be here,” Post said. “We’ve got all brand-new equipment, and this is an excellent school with an excellent administration.”

While there are countywide plans to create a new education center for students to get hands-on workforce experience, Post doesn’t believe officials will ever stop teaching the manufacturing and construction classes at NPHS. In fact, next school year they will start accepting students from other districts to take the NPHS construction classes.

Post said that while it’s time for him to move on to the next phase of his life in retirement, he’s happy knowing the program is in good hands and will develop even further with Tarplee making sure students take the next step — getting internships during their fourth year in the program.

“When students leave here, we want them walking out with a lot of hours of experience and in most of our classes they’re getting college credit and even some certifications,” Post said. “More importantly, the next step is getting the students industry experience because, while they have us as advocates, they need to get out and make connections in the work world.”

Post says it’s difficult to step away from something he helped build and truly loves, but he feels good about the direction the program is going with some 300 students already involved in manufacturing and construction classes.